Largest Fleet of Fourslide Machines in Northeast

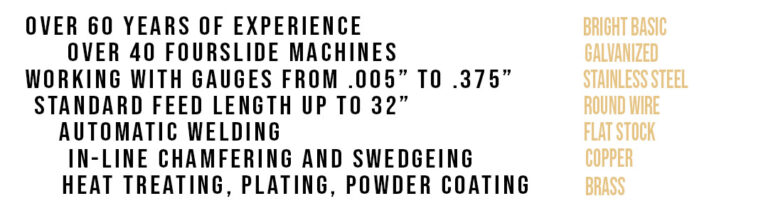

With Over 40 four-slide machines ranging from size “00” – “5” , we have the capacity to get your job done.

Our amazing team of engineers and toolmen build tools and dies in-house using only the highest quality steel.

Tightest Industry Tolerances and Superior Quality Control

We build custom built gauges for each custom part so we can hold some of the tightest tolerances in the industry.

Automated Welders, Chamfering, Wedging and Assembly

We can weld, chamfer and swedge in the forming machine automatically avoiding hand labor expense. We can also provide assemblies and we can count and bag components.

Heat Treating, Powder Coating and Plating

We can provide decorative, strengthening or corrosion resistant finishes. Among what we offer are:

- Heat Treat

- Passivate

- Zinc Plate

- Nickle Plate

- Powder Coating

- Cleaning

We can pack parts according to a wide variety of customer needs and specifications, often make suggestions toward cost savings and how best to avoid “tangling issues”.